MSAcase: The Pinnacle of Aluminum Case Manufacturing & Custom Solutions for Modern Business

In the competitive landscape of industrial design and protective case solutions, choosing a reliable manufacturer with a proven track record is fundamental for businesses seeking durability, customization, and innovation. https://www.msacase.com/ stands out as a leader in aluminum case manufacturing and offers comprehensive custom aluminum case solutions tailored to diverse industries and applications.

Why Aluminum Cases are the Ultimate Choice for Business and Industry

Aluminum cases have revolutionized how organizations protect sensitive equipment, transport delicate instruments, and present products in a professional manner. Their exceptional properties include lightweight construction, superior strength, corrosion resistance, and sleek aesthetic appeal. These features make aluminum cases the preferred choice across sectors such as aerospace, military, electronics, medical devices, broadcasting, and luxury branding.

Unmatched Durability and Strength

Aluminum's inherent toughness ensures that cases can withstand harsh environmental conditions, impacts, and rough handling without compromising the contents. This resilience is critical for industries where equipment safety is paramount.

Lightweight for Ease of Transportation

Compared to traditional steel or heavy-duty plastics, aluminum provides a combination of strength and lightness, reducing shipping costs and making mobility easier for users who frequently travel or transport equipment.

Corrosion Resistance for Long-Term Use

With advanced anodizing and protective finishes, aluminum cases resist corrosion, extending their service life even in humid or salty environments. This feature ensures investment durability and reduces maintenance costs.

Elegant Appearance for Brand Enhancement

Aluminum cases offer a sleek, modern aesthetic that enhances brand image and perception. They serve as replaceable marketing and presentation tools, leaving a lasting impression with clients and partners.

Custom Aluminum Cases: Tailoring Solutions to Unique Business Needs

One size rarely fits all in the world of business equipment and product presentation. Recognizing this, https://www.msacase.com/ excels in creating custom aluminum cases tailored precisely to client specifications, ensuring optimal fit, function, and aesthetic alignment with brand standards.

Design Flexibility and Precision Manufacturing

The company's advanced manufacturing processes include CNC machining, precision cutting, welding, and finishing, enabling complex geometries and intricate designs. Custom features such as foam inserts, interior compartments, lock mechanisms, handles, and branding elements can be incorporated seamlessly.

Industries Benefiting from Custom Aluminum Cases

- Aerospace and Defense: Protective cases for sensitive instruments, avionics, and military equipment.

- Medical and Healthcare: Secure transport of delicate medical devices, samples, and pharmaceuticals.

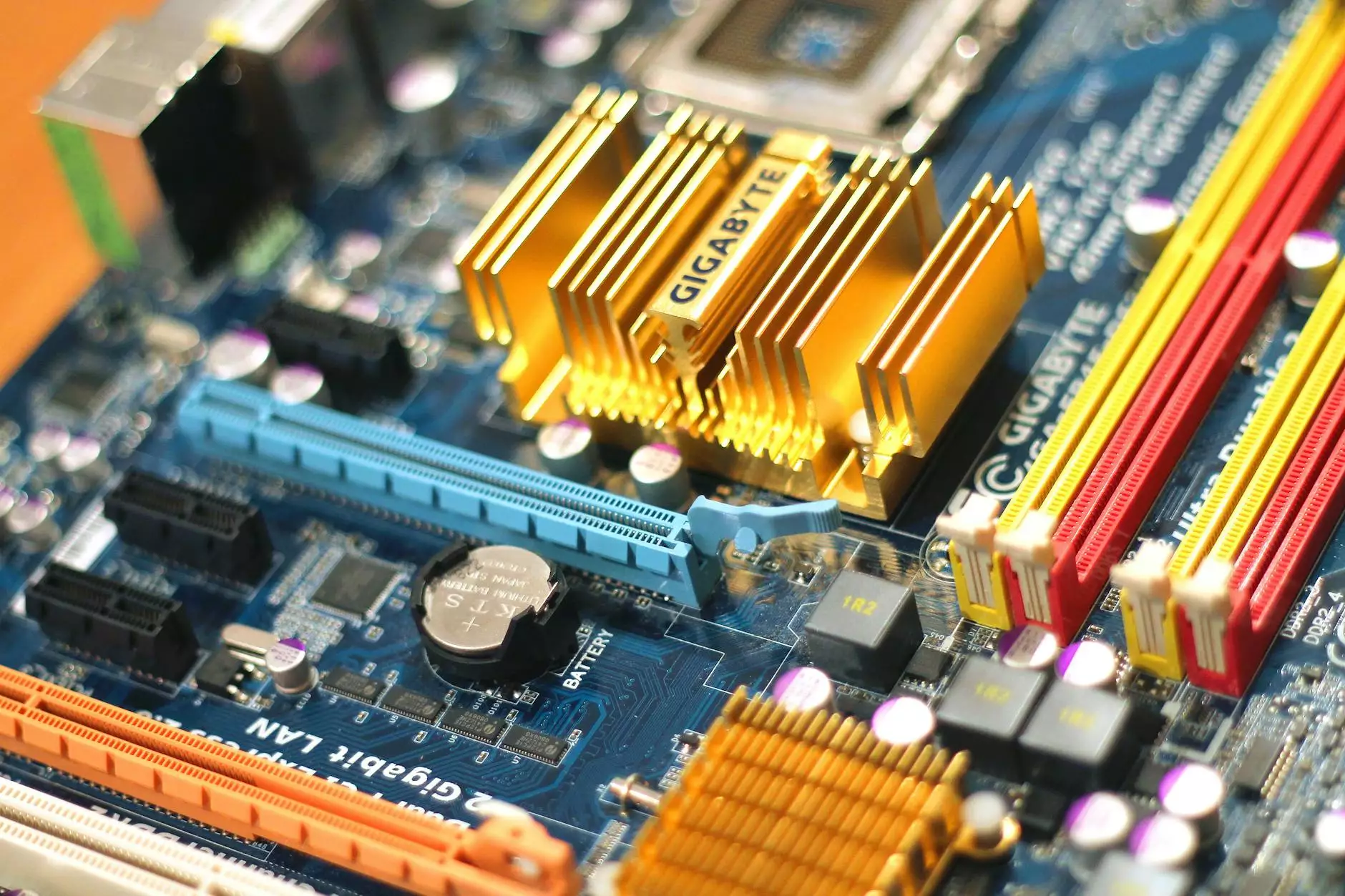

- Electronics and Technology: Housing for sensitive electronics, testing equipment, and portable devices.

- Photography & Broadcasting: Durable cases for camera gear, monitors, and sound equipment.

- Luxury Goods & Branding: Elegant, branded cases that reflect premium quality and aesthetics.

The Manufacturing Excellence of MSAcase

At the core of MSAcase is a commitment to excellence in craftsmanship, innovation, and customer-centric solutions. Their manufacturing process involves several critical phases, ensuring each case meets exacting standards:

Material Selection and Quality Control

Only premium-grade aluminum alloys are used, sourced from reputable suppliers to guarantee strength, corrosion resistance, and consistency. Rigorous quality control protocols are implemented throughout the production cycle, including inspection of raw materials, semi-finished components, and final products.

State-of-the-Art Production Facilities

The company invests in cutting-edge CNC machining centers, precision welding equipment, anodizing, and finishing tools. This technological edge allows for intricate customization, rapid prototyping, and large-volume production with precision and efficiency.

Sustainable Manufacturing Practices

MSAcase emphasizes environmentally responsible production, employing eco-friendly anodizing and recycling aluminum waste. Their sustainable approach aligns with modern corporate social responsibility expectations, appealing to eco-conscious clients.

Advantages of Partnering with MSAcase for Your Aluminum Case Needs

Choosing MSAcase provides unparalleled benefits, including:

- Superior Customization: End-to-end design support, personalized features, branding options, and interior configurations tailored to your application.

- Cutting-Edge Innovation: Integration of advanced hardware, hinges, locks, and protective technologies.

- Consistent Quality: ISO-certified processes guarantee reliability and precision in every product.

- Fast Turnaround Times: Efficient production cycles and responsive customer service ensure timely delivery.

- Cost-Effective Solutions: Optimized manufacturing processes reduce costs without compromising quality.

- Global Reach: Extensive logistics network facilitates international shipping and distribution.

- Comprehensive Support: Expert guidance from conceptual design to post-sales service.

Innovative Applications and Case Studies

MSAcase has a rich portfolio of successful projects across various sectors. For example:

- Military-grade Cases: Custom-designed, rugged cases for portable communication devices that withstand extreme environmental conditions.

- Medical Equipment Transport: Specialized cases with antimicrobial coatings, cushioning, and secure locking mechanisms for sensitive medical tools.

- Electronics Protection: Lightweight yet durable cases for high-end electronics, with shock absorption and customizable foam interiors.

- Branding Excellence: Branded cases for luxury products that combine security with aesthetic appeal and enhance brand perception.

How to Commission Your Custom Aluminum Case with MSAcase

Engaging with MSAcase for a customized aluminum case is straightforward and efficient. The process involves:

- Initial Consultation: Sharing your specific requirements, including dimensions, application, and aesthetic preferences.

- Design & Prototype: The MSAcase team collaborates closely to develop design concepts, 3D models, and prototypes for review.

- Production Planning: Finalizing manufacturing details, material selection, and interior configurations.

- Manufacturing & Quality Control: Precise fabrication, finishing, assembly, and stringent testing of the final product.

- Delivery & Support: Fast shipping, installation guidance, and ongoing customer support.

Conclusion: Why MSAcase is Your Trusted Partner for Aluminum Cases

MSAcase blends innovative manufacturing techniques, premium materials, and customer-focused services to deliver engineering excellence in aluminum cases. Their dedication to quality, customization, and sustainability makes them the ideal partner for businesses looking to safeguard their assets, improve presentation, and enhance operational efficiency.

Whether you need a standard model or a fully customized aluminum case crafted to your specifications, https://www.msacase.com/ is committed to transforming your ideas into durable, elegant, and functional solutions. Invest in a trusted manufacturer that understands the critical importance of quality and innovation for your business success.